charpy impact test value for mild steel|charpy impact chart : distribution The Charpy Impact Test is a destructive material method. This test method provides information about the material’s resistance to sudden stress. The toughness depends on three factors: 1) temperature; 2) notch form, and; 3) the material’s composition or the resulting lattice structure. webJames Horncastle. Jan 19, 2022. 27. Over a freshly squeezed orange juice by a marina in Ibiza, Theo Hernandez scratches the back of his head and laughs. Sat across from him, bronzed and in a white .

{plog:ftitle_list}

Rated the best text to speech (TTS) software online. Create premium AI voices for free and generate text-to-speech voiceovers in minutes with our character AI voice generator. Use free text to speech AI to convert text to mp3 in 29 languages with 100+ voices.

The Charpy Impact Test is a destructive material method. This test method provides information about the material’s resistance to sudden stress. The toughness depends on three factors: 1) temperature; 2) notch form, and; 3) the material’s composition or the resulting lattice structure.This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test .The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .In this investigation, we performed instrumented Charpy tests in order to characterize the impact properties of three steels, used by NIST for the production of Charpy reference specimens .

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a .The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110.

The Charpy Impact Test, also known as a V-notch test, evaluates a material’s impact strength by measuring the energy required to fracture a standardized sample with a machined V-notch. Using a released pendulum, .

The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .This paper presents the results of Charpy impact test on Mild steel as measured impact force time history. A detailed Finite Element model of the Charpy impact test specimen is .According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significant Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.

Charpy impact tests were performed on mild steels with body-centered cubic (BCC) crystal structures for comparison with the test results of welded austenitic stainless steels with face-centered . Quantitative data is data based on numerical values. In the Charpy impact test, this quantitative data is normally the energy absorbed during the fracture of the sample. The DBTT (Ductile-to-Brittle Transition Temperature) can also be estimated by testing the multiple samples at multiple temperatures to see where there is a drastic increase in .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the amount .Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .

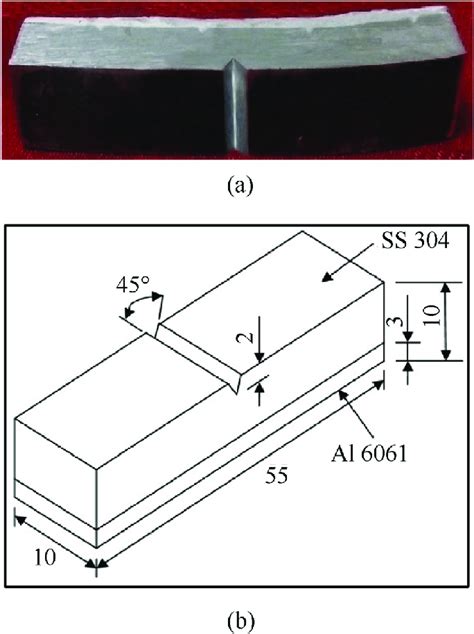

2.3 Metallographic Characterizations. The specimens were well welded with double grooving of the butt joint. The cross-section of welded metal is shown in Fig. 3.The two specimens (34 mm × 30 mm × 4.5 mm) were welded by the ABSMAW and then the welded metals machined with (55 mm × 10 mm × 4.5 mm) according to the ASTM E23 (Charpy test) standard, as . The ductile–brittle transition temperatures (DBTT) from the (corrected) test data are determined for the two materials based on the criterion of 20.4 J (15 ft-lb) absorbed energy.Fracture toughness values of the DP590 steel were also obtained through the correlation with the Charpy impact energy data. History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness of materials, particularly metals. His work led to the creation of the Charpy impact test, which involved striking a standardized specimen with a .EXPERIMENTAL ANALYSIS OF IMPACT STRENGTH AND COMPARISON OF IMPACT .

This value, 149.614 joules, represents the energy the material absorbed during the impact, and it helps determine whether the material is tough or brittle. . While commonly used for metals like steel, Charpy impact test aluminum and other non-ferrous metals can also be performed, providing critical insights into these materials' performance . Temperature dependence of the grain size dopt for maximum cleavage fracture toughness in mild steel. Strain rates during Charpy impact testing are such that significant elevation of the yield stress from its "static" value is observed [3, 28]. The average notch strain rate has been calculated to be typically 3000 s-1 [ 29].What is the charpy impact test – The charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material’s notch toughness. The objective of the charpy impact test ?? To determine the material resistance to impact from a .price is higher because steel has toughness. As for the impact price test specimen is different because there are several factors that cause differences in the size of the test specimen, the weight of the pendulum, the length of the pendulum arm, and the difference from the initial angle of the pendulum. Chaerul Umam Wardani et al in 2009 .

“JR” means that the minimum charpy impact value at room temperature is 27J. “J0” refers to the minimum charpy impact value at 0 °C is 27J. “J2” means the minimum impact value at -20 °C is 27J. S275 Data Sheet & Specification. EN .Many notched bar impact tests of different designs and loading have been used to predict brittle fracture of ferritic steels. In the USA, the Charpy specimen has been standardized in ASTM E23 for impact three-point bend testing (ASTM E23 1999).Figure 1 illustrates a standard ASTM type A Charpy impact test specimen. The Charpy three-point bend specimen is more convenient .

This paper presents the results of Charpy impact test on Mild steel as measured impact force time history. A . Berdin.C and Prioul.C: Determination of the fracture toughness of a low alloy steel by the instrumented Charpy impact test. International Journal of Fracture 2002, 115: 205–226. [4] Hisashi Serizawa, Zhengqi WU, Hidekazu Murakawa .

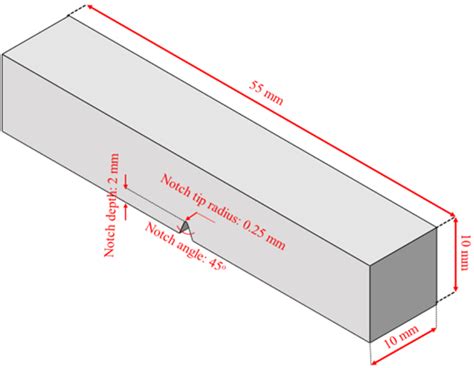

The samples are then subjected to Charpy impact testing as per ASTM-E23.The Charpy impact tests were conducted at room temperature and energy values were measured. The hardness before and after heat treatment processes for EN8 steel specimens were measured.After that specimens were polished and introduced a 45˚ V-notch, 2 mm deep with .

“JR” indicates the quality grade related to Charpy impact test energy value ≥ 27 J at room temperature (20 °C); “C” indicates the material is suitable for cold flanging, cold bending, cold forming or cold drawing, e.g. S235JRC (1.0122). 1.0038 is the designation of steel number. S235JR steel general delivery conditions are as follows:

For mild steels intended for service temperatures down to -20 to -30 C it is normal to prescribe a Charpy V-notch test with a minimum requirement of 2.8 kgf∙m. Experience has proved that this is a satisfactory criterion for this type of steel. . A minimum impact energy of 3.5 to 4.15 kgf∙m at test temperatures immediately below service . The authors validated this method for mild steel by comparing with the experimental results obtained using an instrumented Charpy impact testing machine, which helped measure the impact load and load point displacement [14, 15]. The adiabatic heating due to plastic dissipation was considered in this analysis.

Determination of Johnson cook material and failure model constants and numerical modelling of Charpy impact test of armour steel . Charpy Impact Test on Mild Steel. . After the impact, the load quickly rose to a peak value of around 30 kN within a time interval of around 0.355 ms and thereafter died down to zero value in about 2 ms. The .

Laboratory pulp dehydrator distributor

ASTM A36 Steel. ASTM A36 steel is one of the most widely used carbon structural steels, although the carbon content of A36 material is maximum 0.29%, it is considered to be the mild steel (content of carbon ≤ 0.25%).. A36 mild steel is often compared to AISI 1018, A36 carbon steel is commonly hot rolled, while 1018 steel is commonly cold rolled.. Notes: There are two . In order to reveal the toughness of our designed steel, standard Charpy V-notch impact samples were prepared. Ultrahigh Charpy V-notch toughness of 300–450J was achieved with strength as high as .The Charpy impact test is extensively used in the industries due to simplicity of test . Bar diagram of Charpy impact energy values of mild steel and EN8 steel as a function of heat treatment processes. Fig. 7. Bar diagram of Rockwell hardness (Rc) of . The paper presents and analyzes the results of experimental tests performed on two non-alloy low carbon steels (1.1141 and 1.0122) in cases of their exposure to impact fracture energy and uniaxial high cyclic mechanical stress-controlled fatigue. The experimental results provide insight into the changes in the Charpy impact fracture energy of the V-notched test .

charpy test sample dimensions

charpy impact test standard pdf

webLindomar (@lindomar284) no TikTok |2.5K curtidas.274 seguidores.Assista ao último vídeo de Lindomar (@lindomar284). Passar para o feed de conteúdo. . #FakeNews #JornalFake #Meme #CapCut #pedecana #mizeravel # lindomar284. Lindomar. #FakeNews #JornalFake #Meme #CapCut #pedecana #mizeravel # som original - Lindomar. 1. .

charpy impact test value for mild steel|charpy impact chart